Accurate Prediction of Distortion & Residual Stress

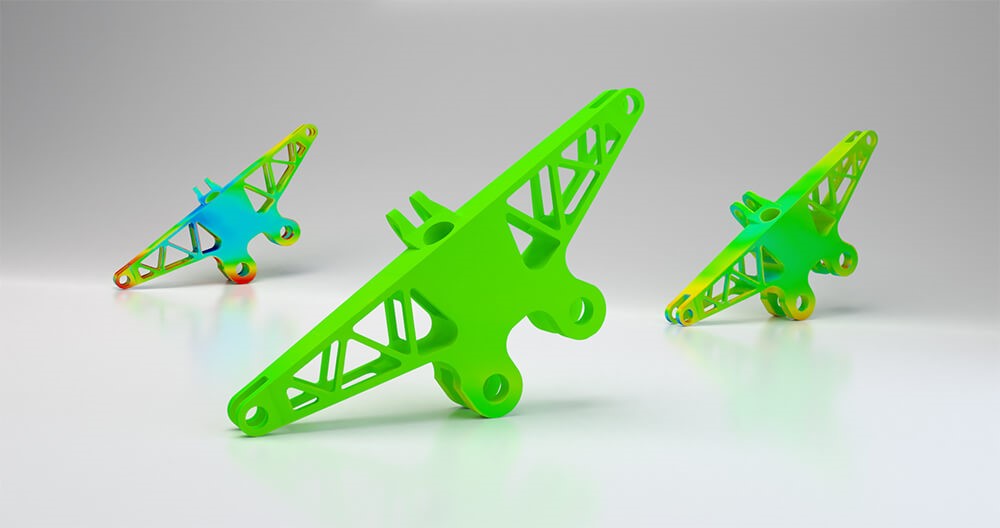

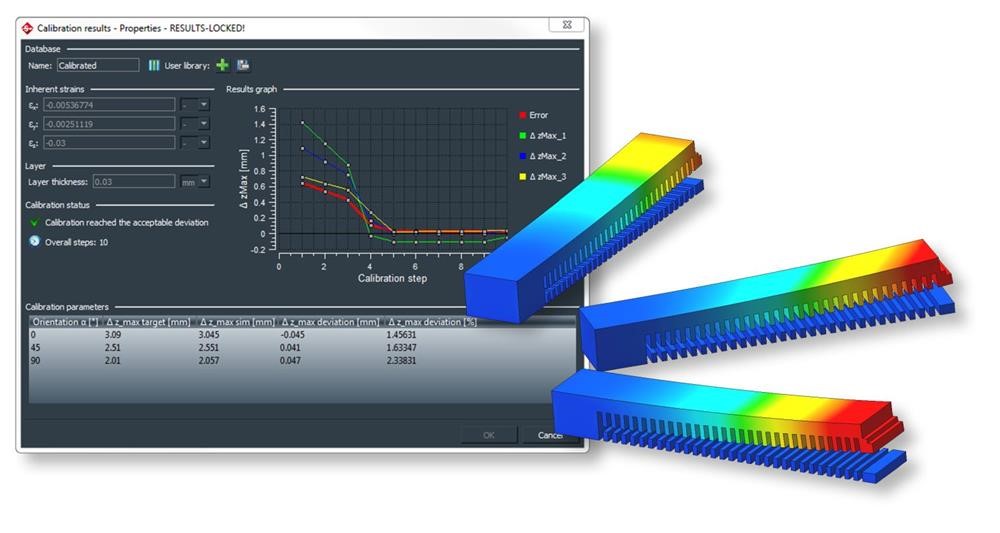

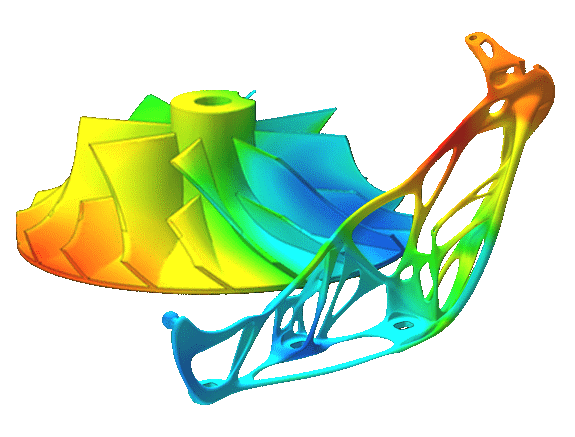

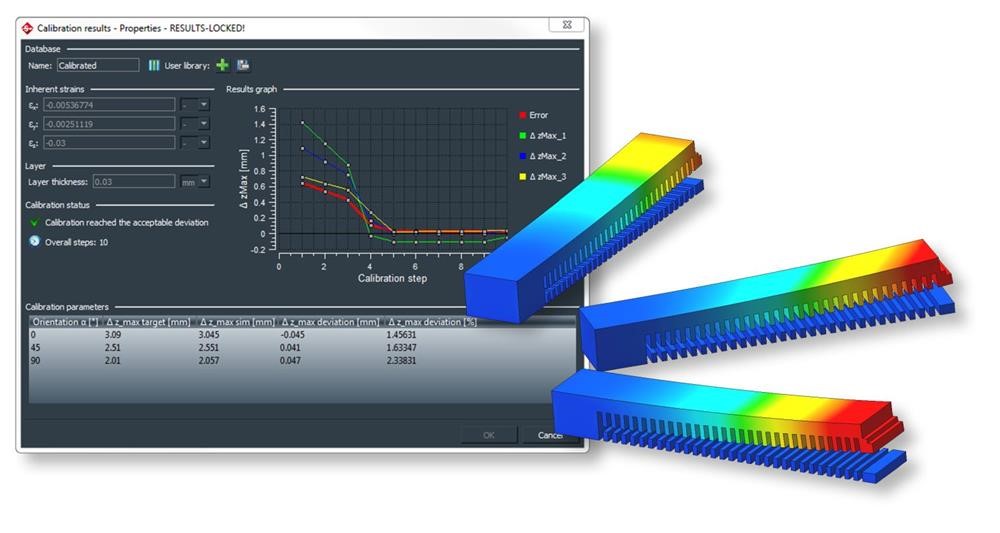

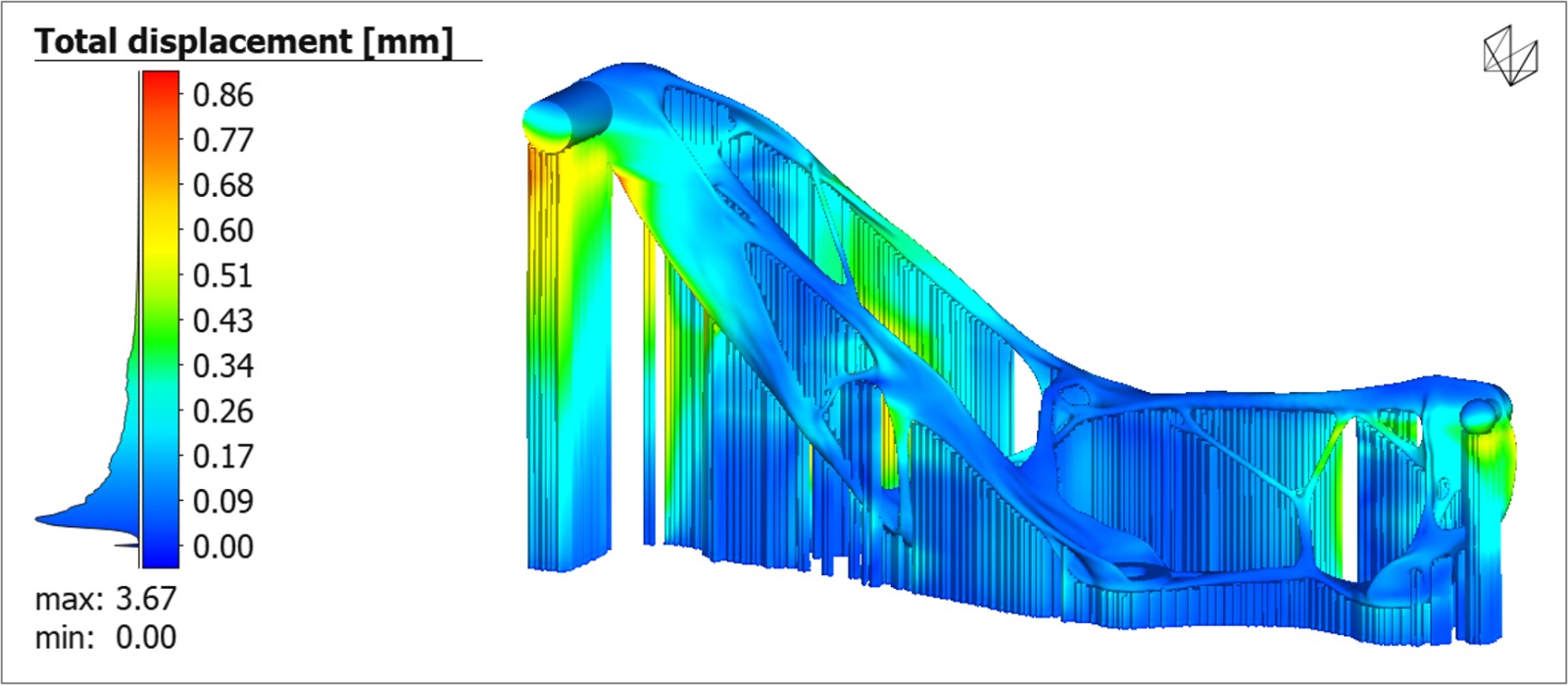

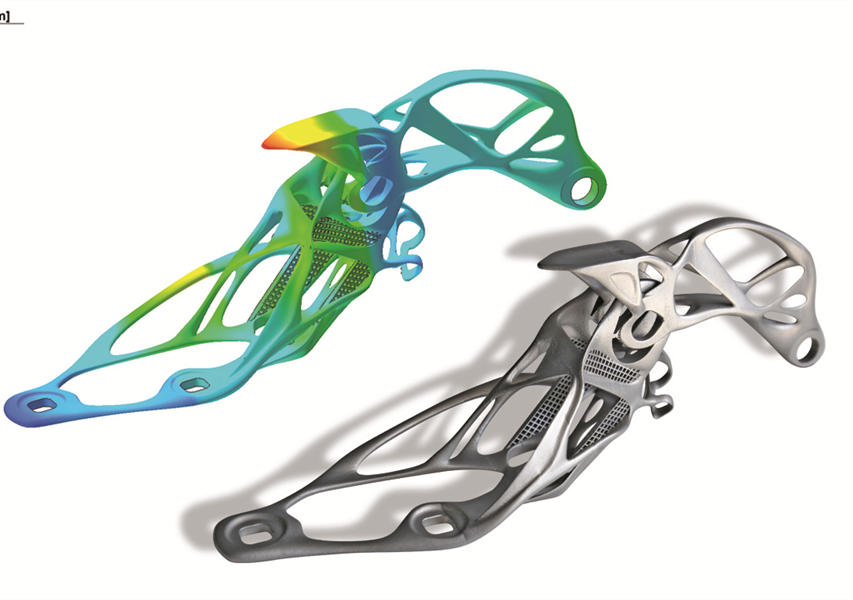

- Identify areas prone to warping, cracking, or recoater interference

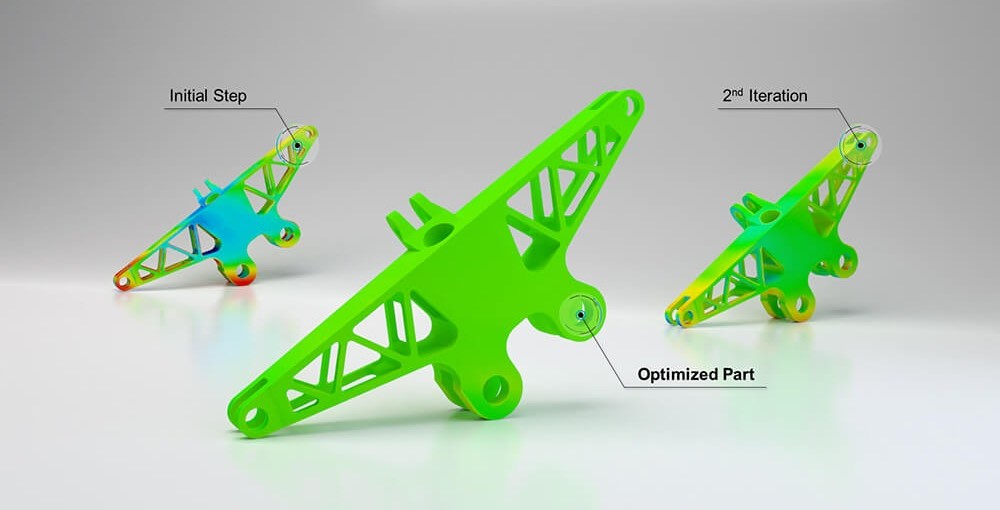

- Minimize trial-and-error with virtual iteration

At Additives Industries, we use Simufact Additive by Hexagon, a leading simulation software purpose-built for metal additive manufacturing, to ensure precision, reliability, and cost-efficiency in every part we produce.

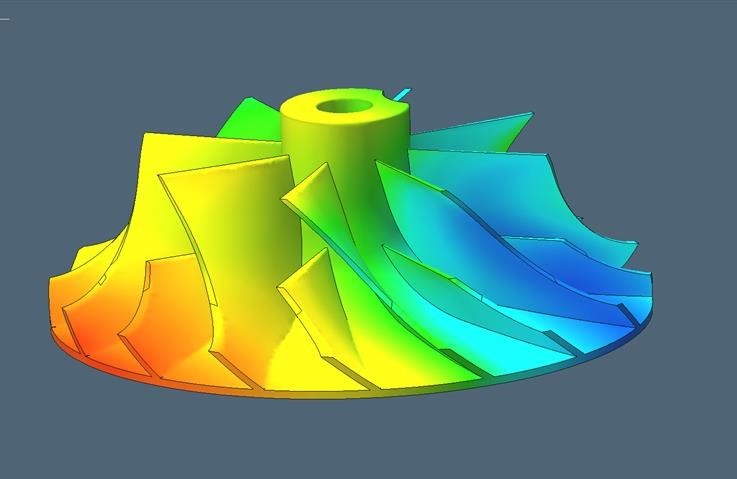

Simufact Additive is a powerful simulation platform designed specifically for the Laser Powder Bed Fusion (LPBF) process. It allows us to predict thermal and mechanical behavior during printing, helping us optimize part orientation, support structure design, and residual stress mitigation before manufacturing begins.

Developed by Hexagon Manufacturing Intelligence, a global leader in engineering software and digital manufacturing, Simufact is trusted across industries including aerospace, automotive, energy, and medical.

Purpose-built simulation for LPBF that reduces trial-and-error and delivers first-time-right results.

Simufact Additive is developed by Hexagon, a global leader in smart manufacturing and metrology. Their

technology is at the forefront of digital engineering, empowering companies like Additives Industries to

bridge the gap between design and production.

Learn more about Hexagon:

https://hexagon.com