Refining and finishing your 3D printed metal parts for performance, reliability, and application readiness

Wire EDM is used to cleanly separate parts from the build plate, especially when tight tolerances or complex geometries are involved. It ensures base removal without damaging critical surfaces.

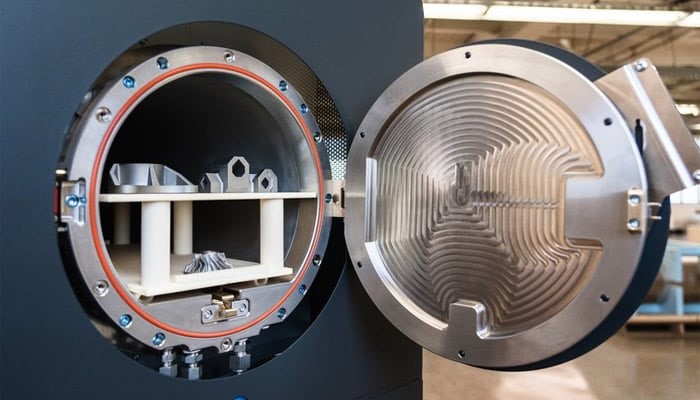

After printing, parts undergo a controlled heat treatment process to reduce residual stresses induced during rapid heating and cooling. This ensures dimensional stability and improves mechanical properties.

Our technicians carefully remove supports using a combination of mechanical tools and precision finishing methods. This prevents damage to fragile or internal geometries.

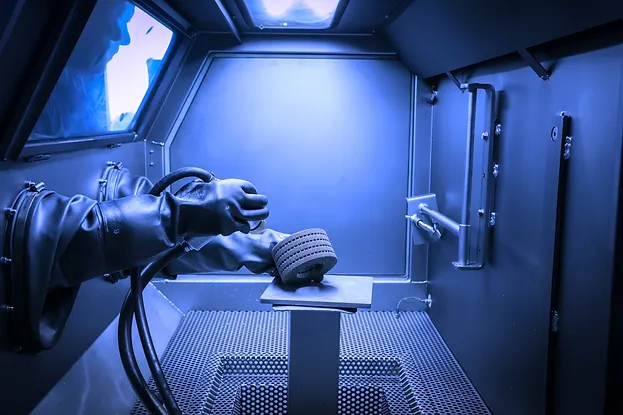

We apply controlled blasting with spherical media to induce beneficial compressive stresses on the surface, improving strength and fatigue performance.