At Additives Industries Pvt. Ltd., we offer a range of TRUMPF industrial laser machines renowned for their precision, reliability, and flexibility. These systems are essential tools for subtractive post-processing, part assembly, and permanent part identification, making them indispensable in metal additive manufacturing workflows.

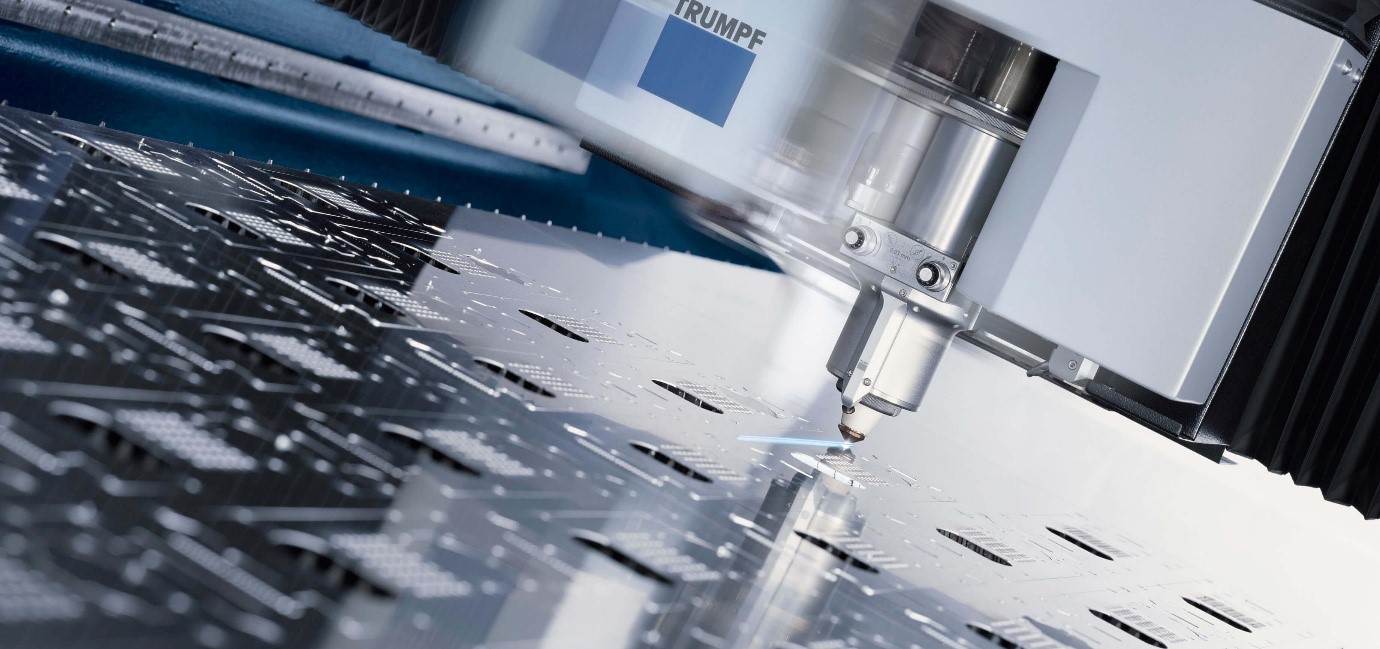

High-Speed, Precision Sheet Metal Cutting

TRUMPF’s laser cutting machines are engineered for cutting complex 2D and 3D geometries with high accuracy and minimal material waste. These machines use CO₂ or fiber lasers, depending on the application, and are ideal for thin to thick sheet metal processing.

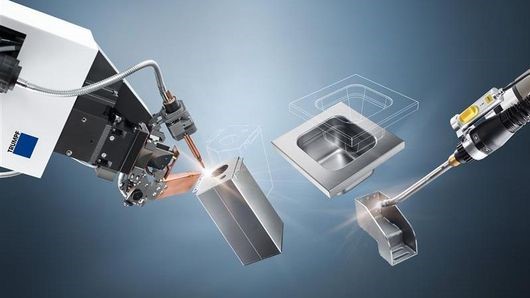

Precision Joining for Functional Assemblies

TRUMPF laser welding systems enable high-strength, low-distortion joining of metal components—including additively manufactured parts. Suitable for spot welding, seam welding, and deep penetration welding.

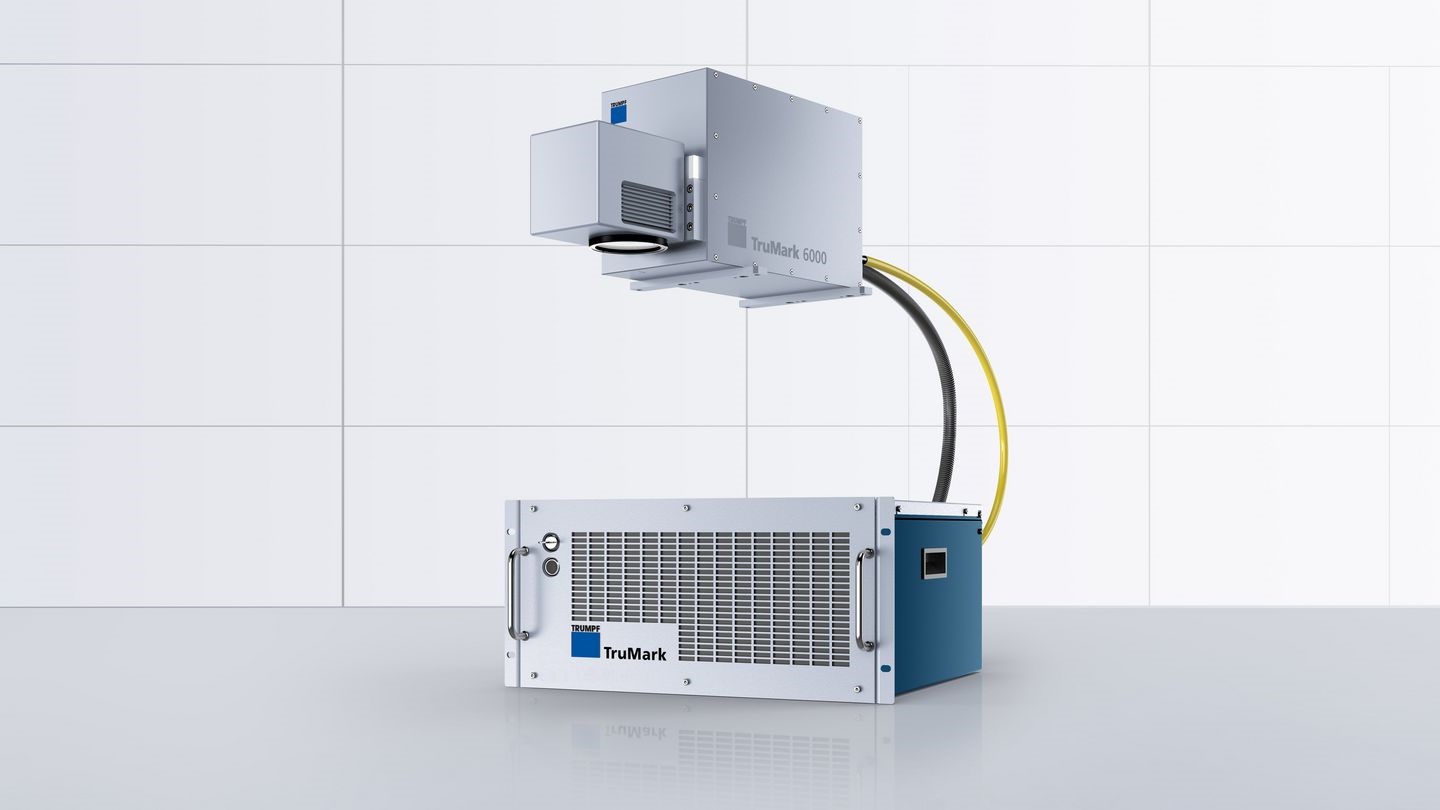

Permanent Identification & Traceability

TRUMPF’s laser marking machines offer high-speed, non-contact engraving of metal components with micron-level precision. Perfect for part traceability, branding, serial numbers, and QR/barcode engraving.

German Engineering Excellence – Industry-leading precision and durability

Seamless Integration – Works well with AM and conventional manufacturing lines

Automation-Ready – Robotic integration & multi-axis capabilities

Low Maintenance & High Uptime – Designed for continuous industrial operation

Material Versatility – Steel, titanium, aluminum, copper, brass, plastics, etc.

Global Support – Backed by a worldwide service network and expert technical assistance