LPBF builds complex metal parts layer by layer using a high-powered laser that selectively melts metal powder. Unlock intricate, lightweight, and durable components that are hard or impossible with traditional methods.

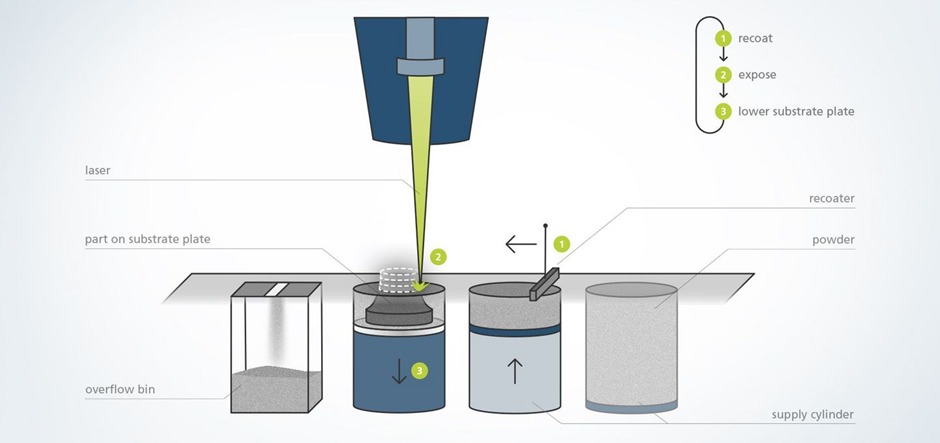

Laser Powder Bed Fusion (LPBF) is an advanced metal additive manufacturing process. A high-powered laser selectively melts regions of a thin powder layer, building parts additively from a digital model with exceptional detail and performance.

Each thin layer of powder (typically 20–100 μm) is precisely fused, enabling fine features and dense parts.

Create internal channels, lattice structures, and organic shapes without the penalties of conventional tooling.

From titanium and nickel superalloys to tool steels—LPBF supports a broad portfolio of engineering materials.

A thin powder layer is spread across the build plate.

The laser fuses areas per the 3D slice data.

The platform lowers, a new layer is applied, and the cycle repeats until complete.

The 3D CAD model defines the final part’s geometry and internal features.

The model is sliced (20–100 μm). Supports and parameters (laser power, scan speed, layer thickness) are defined.

Metrology, CT scanning, and material testing verify accuracy, strength, and internal quality.

Go from idea to high-performance metal parts faster—with less waste and no tooling.

Additive is not just a new tool—it’s a new way of thinking about how we design and produce metal parts.

Lightweight structural brackets, fuel nozzles, heat exchangers.

Patient-specific implants, orthopedic devices, surgical tools.

Conformal cooling inserts and high-strength cutting tools.

Turbocharger components and lightweight supports.

Turbine blades, burner heads, and oil & gas components.

Each alloy family has tuned process parameters to achieve optimal density, microstructure, and mechanical performance.

| Material Family | Common Grades | Key Properties |

|---|---|---|

| Stainless Steels | 316L, 17-4PH | Corrosion resistance, high strength |

| Titanium Alloys | Ti-6Al-4V | Lightweight, biocompatible, strong |

| Nickel-Based Alloys | Inconel 718, 625 | High-temp strength, corrosion resistance |

| Aluminium Alloys | AlSi10Mg | Low density, good thermal conductivity |

| Tool Steels | H13, Maraging Steel | High hardness, wear resistance |

German-engineered precision for performance, repeatability, and industrialized workflows.

From prototypes to production, LPBF enables what was once impossible. Have questions or need a quote? Let’s talk about your part, your material, and your timeline.