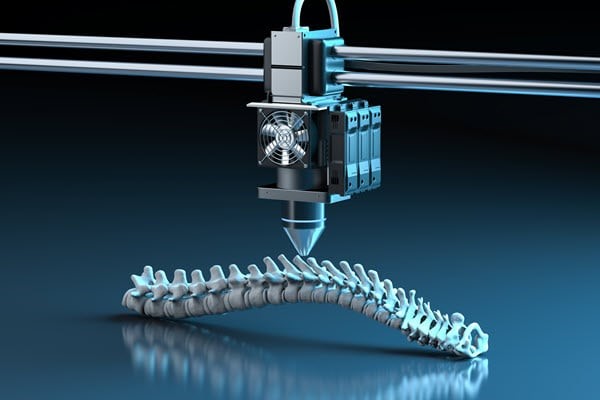

Additives Industries Pvt. Ltd. offers scalable and precision-driven metal 3D printing solutions using advanced Laser Powder Bed Fusion (LPBF) technology. We support production across a wide range of industries, enabling digital manufacturing at reduced costs, faster timelines, and minimal material waste.

Established in 2021 and based in Bangalore, Additives Industries Pvt. Ltd. delivers cutting-edge metal additive manufacturing services to sectors such as Aerospace, Automotive, Medical, Engineering, and Education.

Our expertise spans:

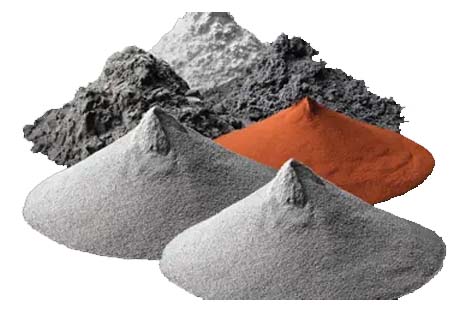

We specialize in producing high-precision parts using premium alloys like Nickel, Aluminium, Titanium while maintaining a strong focus on cost-efficiency, sustainability, and production scalability.

Download BrochureWe transform physical components or conceptual ideas into accurate, print-ready digital models—ensuring manufacturability from the start.

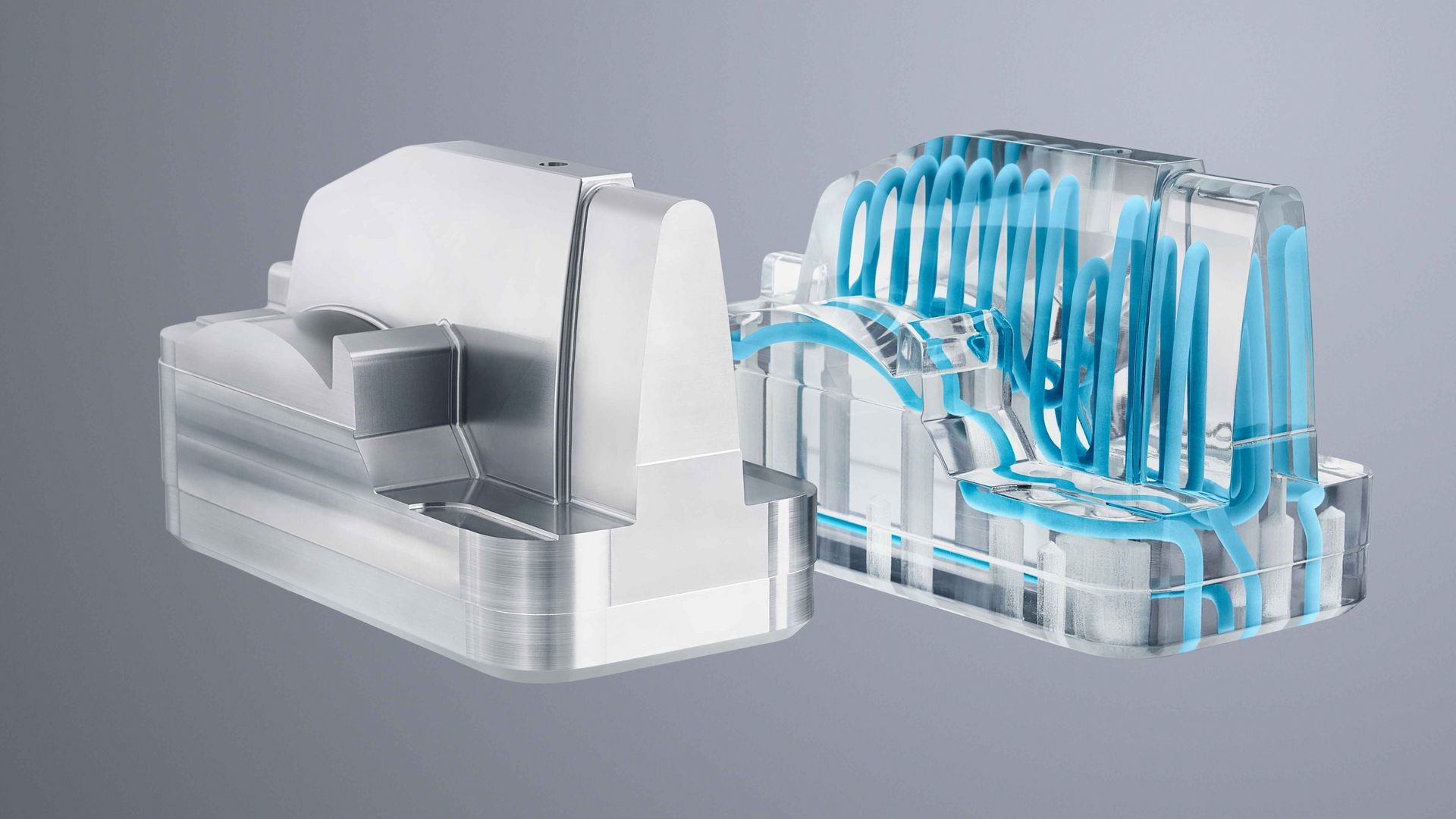

By integrating simulation, printing, and post-processing under one roof, we reduce reliance on third parties and shorten timelines.

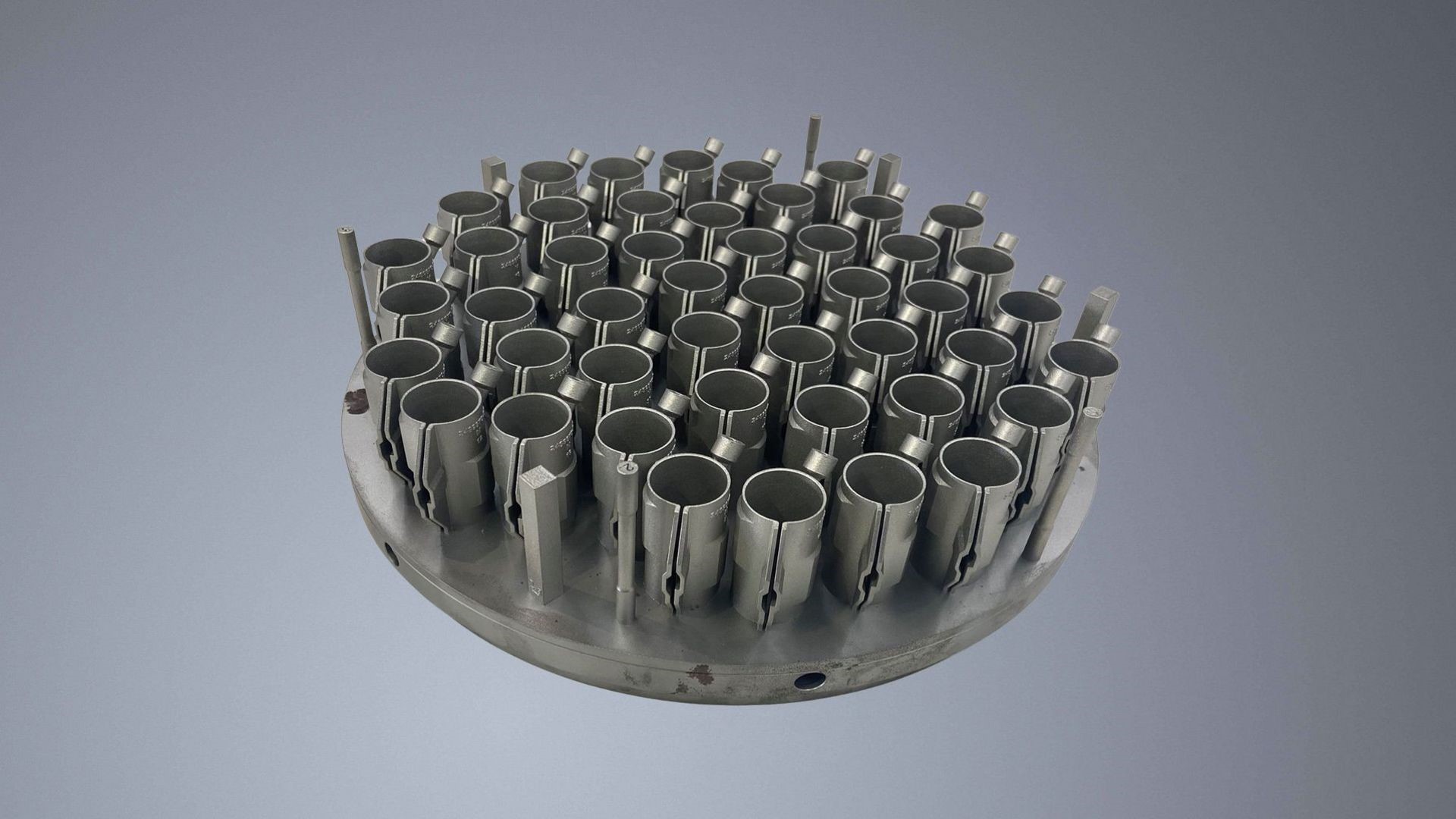

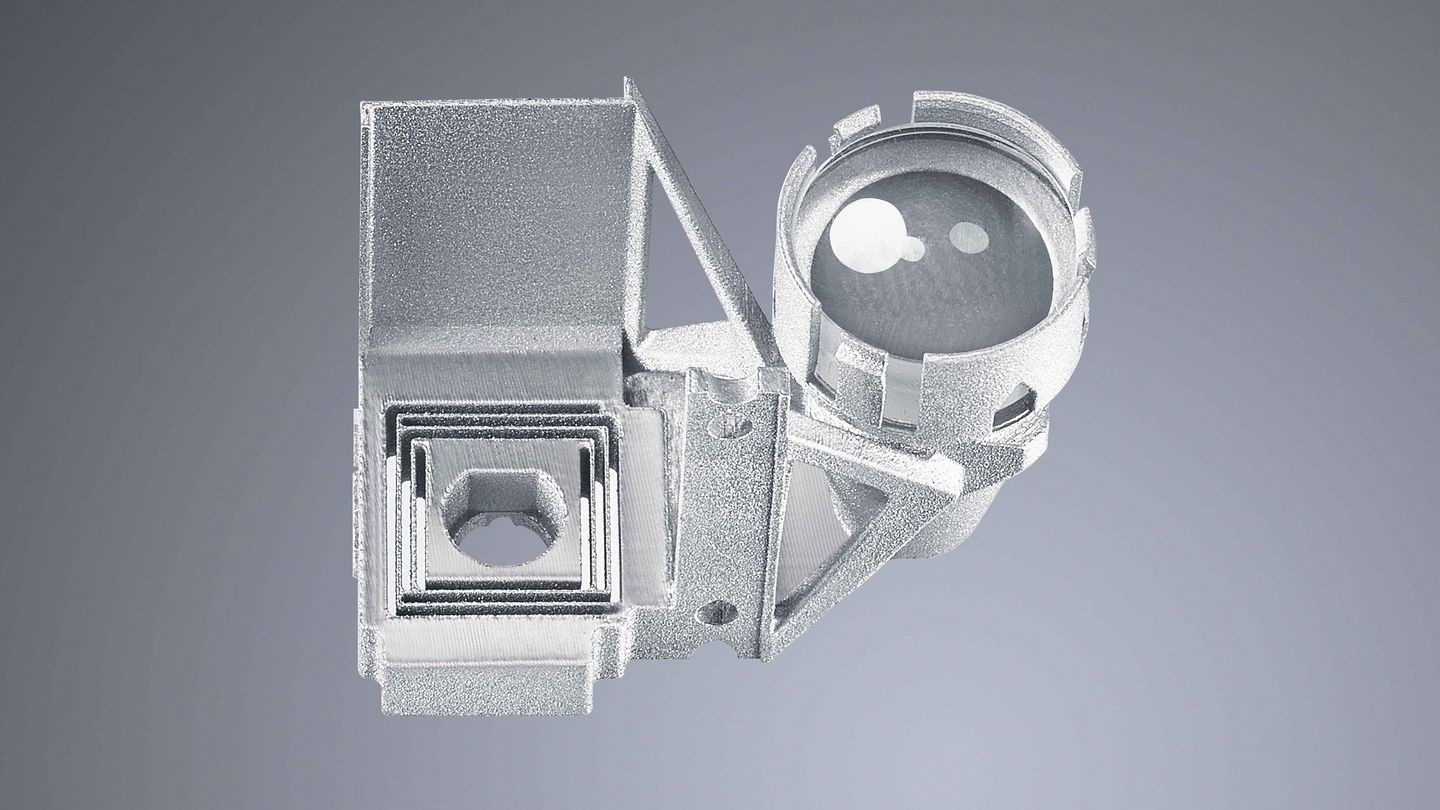

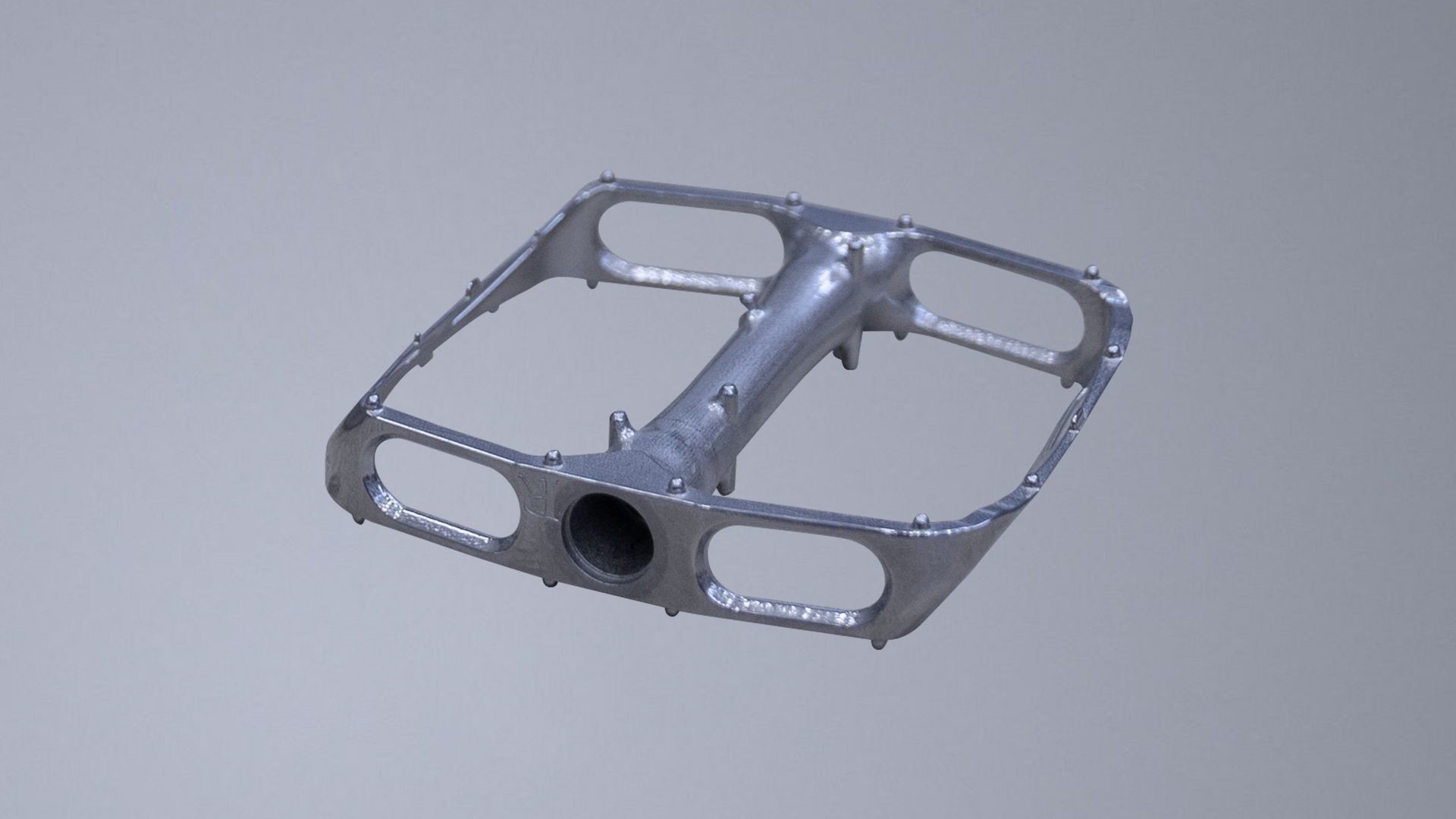

We deliver personalized, application-specific components at industrial scale—ideal for low-volume, high-complexity parts.

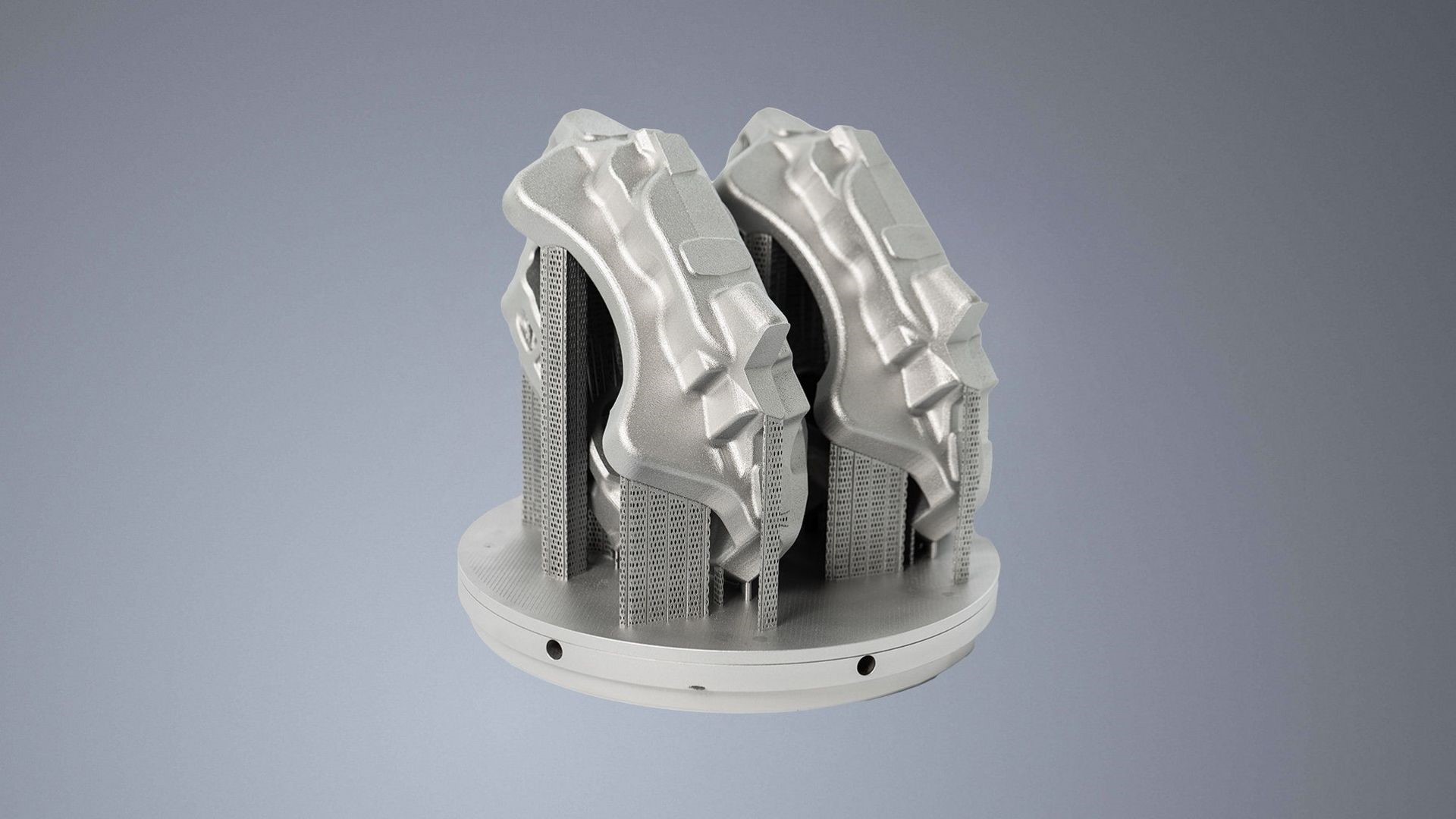

Our LPBF process enables rapid turnaround for prototyping or mid-batch production, with precision in complex geometries.

We optimize every build to reduce powder waste and power consumption—ensuring sustainability without sacrificing performance.

We provide end-to-end solutions for metal 3D printing – from part preparation to finished parts.

Explore our advanced 3D printing solutions, powders, and equipments designed for precision, reliability, and efficiency.

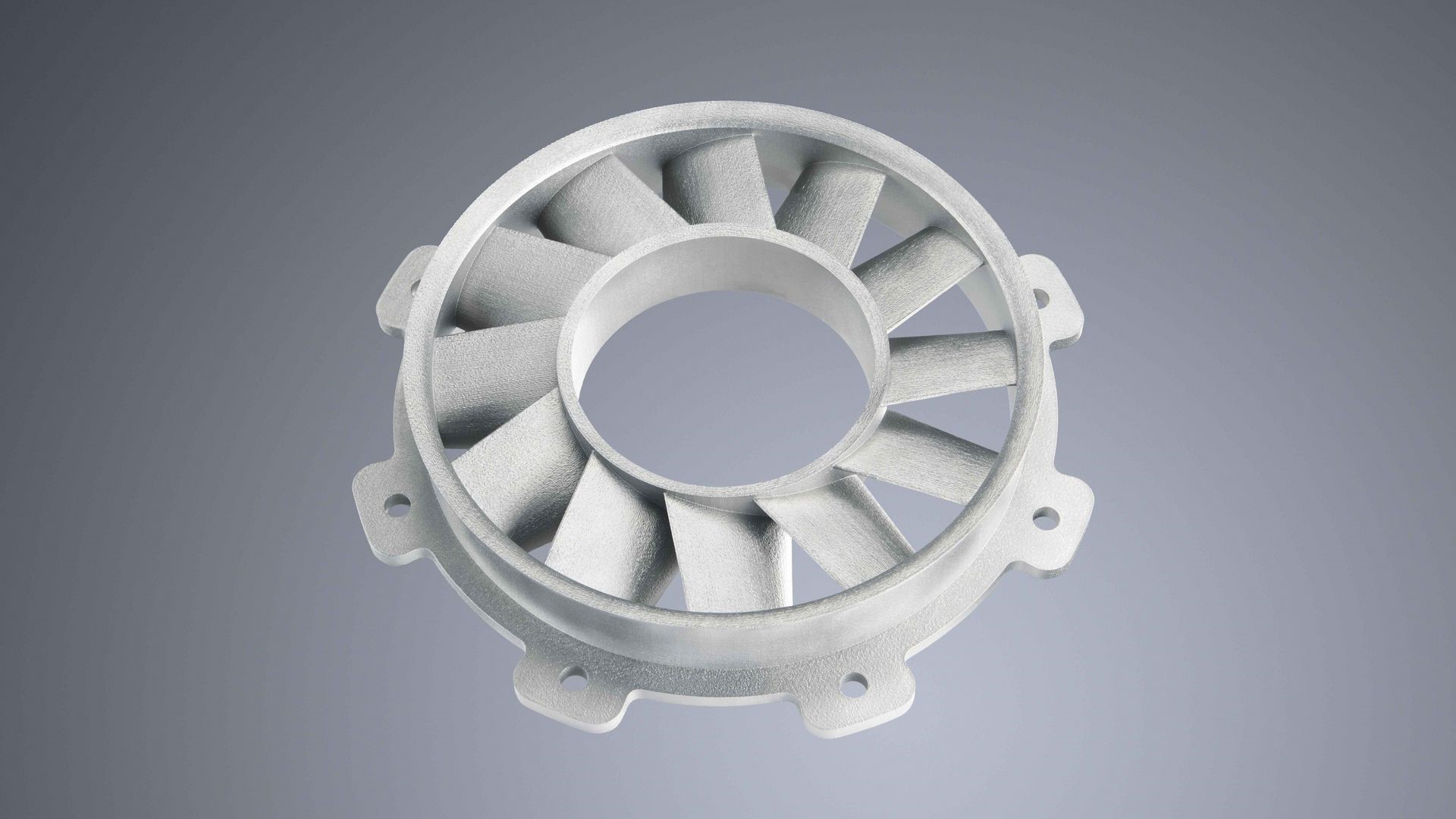

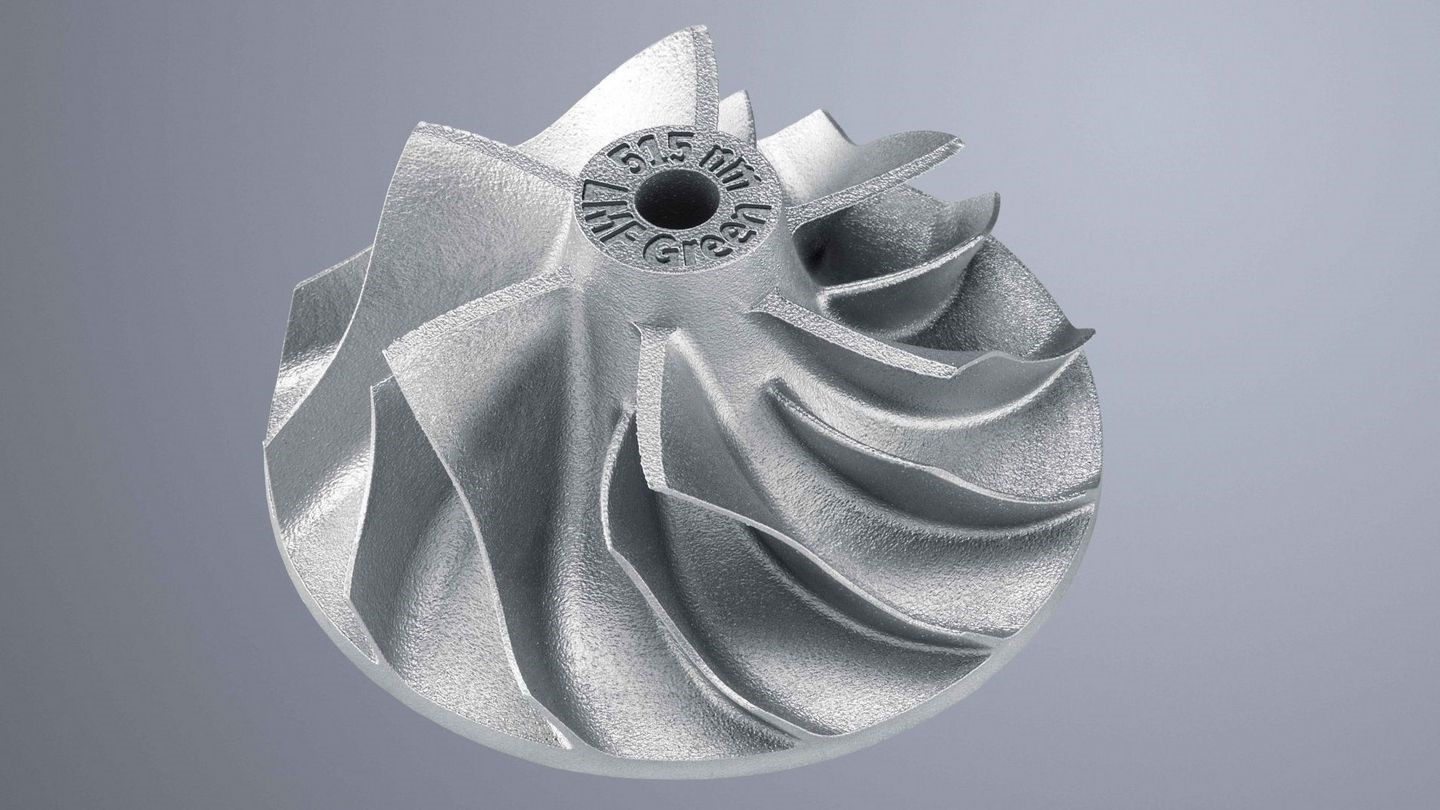

We specialize in delivering high-precision metal 3D printing solutions using Laser Powder Bed Fusion (LPBF) technology. Our expertise spans across multiple industries, enabling lightweight, durable, and complex parts that conventional manufacturing cannot achieve.

Discover how metal additive manufacturing is redefining industries. Metal 3D printed parts deliver precision, durability, and innovation — transforming concepts into real-world solutions for aerospace, automotive, medical, energy, and beyond.

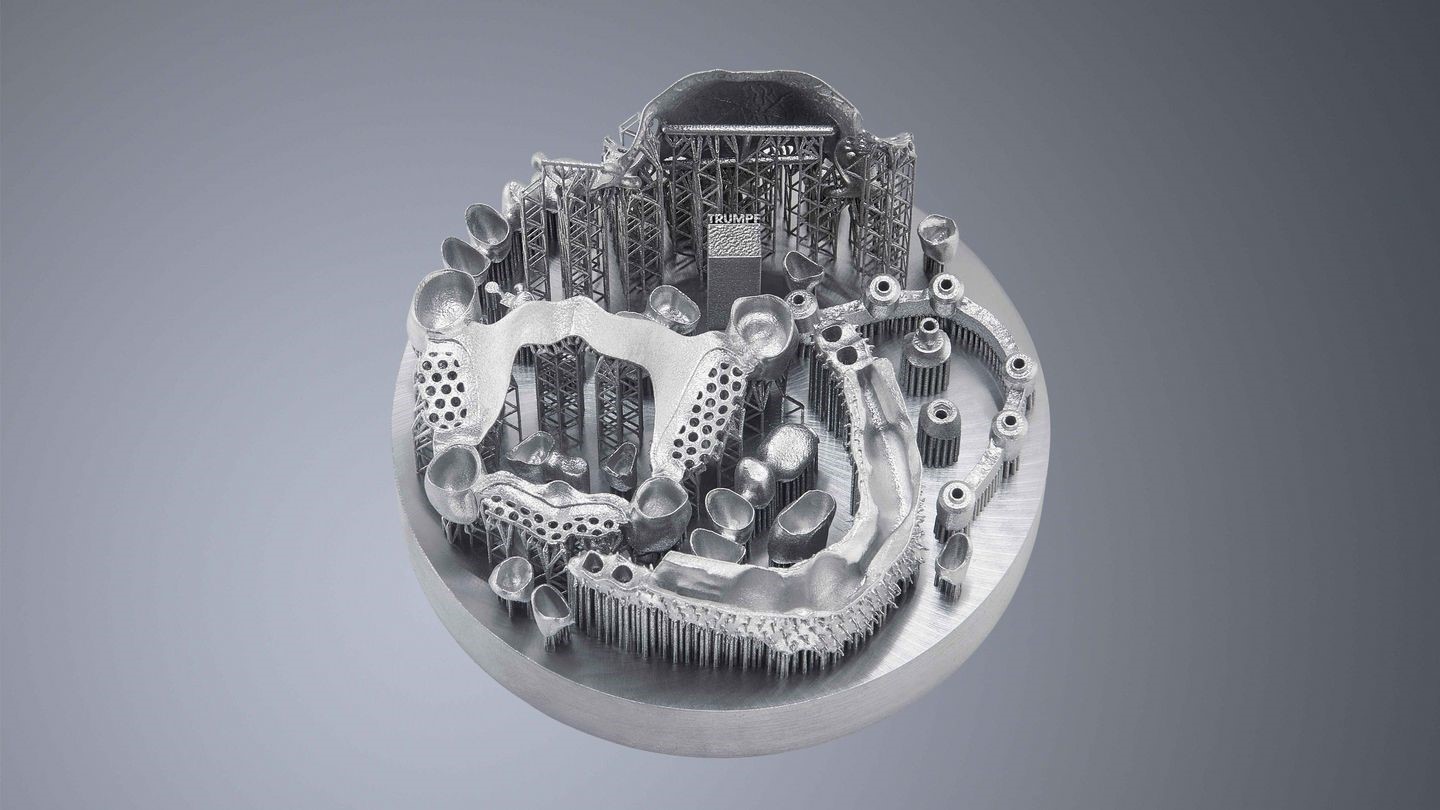

Powered by the TRUMPF TruPrint 3000 for high-precision, customized metal printing.

Ideal for complex geometries and mid-size batch production.

From CAD validation and support generation to post-processing and part delivery.

Seamless, in-house control over the entire production workflow.

Expertise in Printing high-performance metals like Stainless Steel (316L), Nickel (Inconel 718), Titanium and Aluminium.

Material sourcing and parameter optimization for industry-grade quality.

Adhering to top additive manufacturing practices worldwide.

Low material waste and optimized energy use.

Focus on achieving lowest cost-per-part without compromising on quality.

Serving aerospace, automotive, medical, engineering, and education sectors.

Capable of mass customization for functional and performance-driven applications.

Based in Bangalore with quick turnaround and responsive support.

Build simulations and real-time process monitoring to ensure defect-free parts.

Optimized Post-processing activities.