Print complex parts with excellent detail, material strength, and repeatability using TRUMPF TruPrint systems.

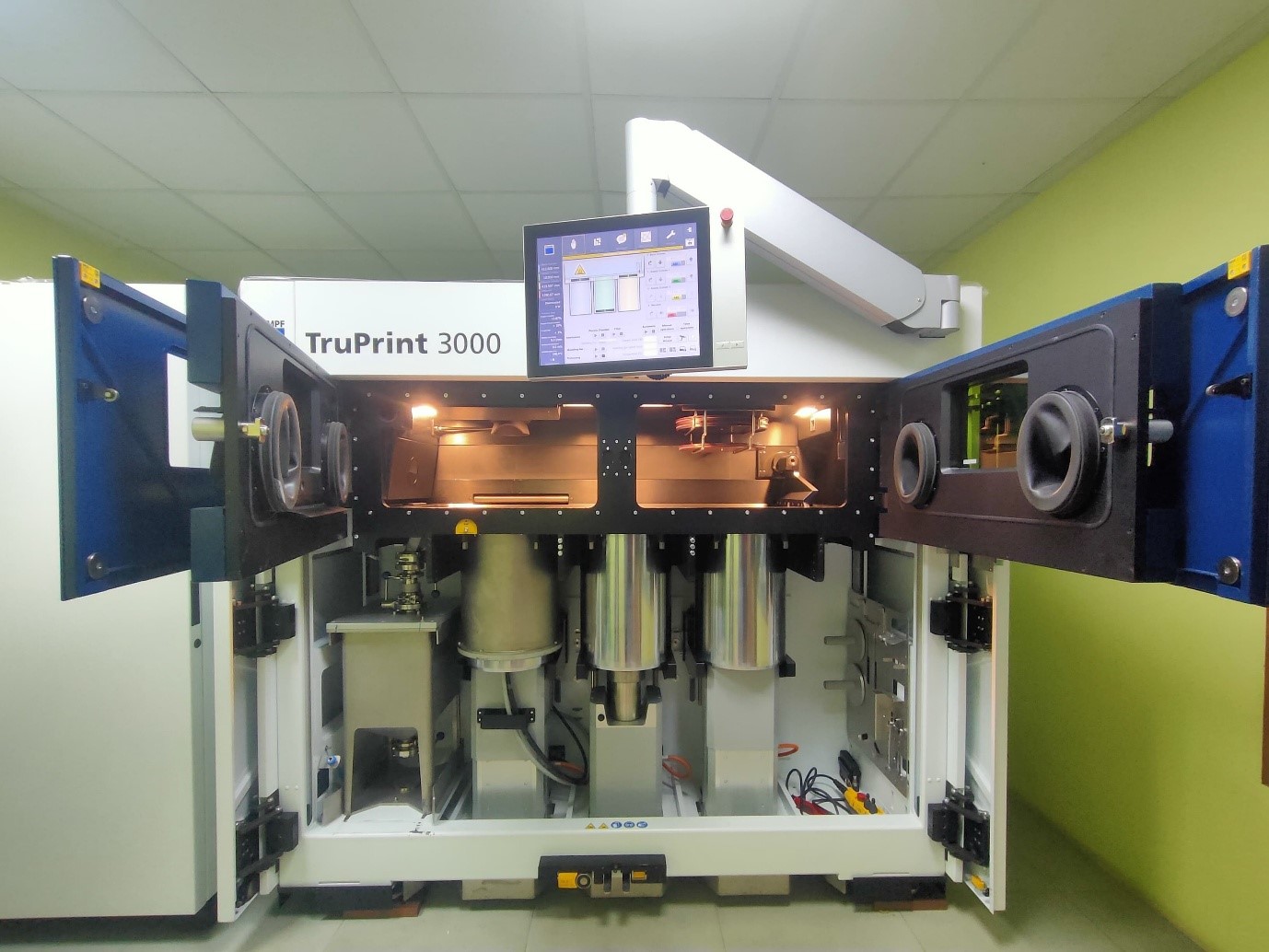

We use the industrial-grade TRUMPF TruPrint 3000, a Laser Powder Bed Fusion (LPBF) system, for functional prototyping and mid-batch production. This system offers superior precision and repeatability using high-performance metal powders.

Ø300 mm × 400 mm

Superior surface finish and mechanical properties.

Stainless Steel, Titanium, Inconel, Tool Steels, Aluminum Alloys

Full control for process optimization and experimentation.

Excellent corrosion resistance and strength for demanding engineering applications.

Lightweight, biocompatible, and high strength-to-weight ratio for aerospace & medical parts.

Nickel-based alloys optimized for high-temperature and corrosive environments.

High wear resistance and hardness, ideal for tooling and high-load applications.

Lightweight, thermally stable, and mechanically robust for advanced manufacturing.

Specialized blends for R&D, prototyping, and high-performance applications.

Internal channels, lattice structures, and undercuts without tooling, enabling innovative designs.

Fully dense components with excellent mechanical and thermal performance.

Minimal waste with optimized support structures and efficient powder usage.

Perfect for regulated industries and serialized production with high consistency.

Open system allows custom process development for advanced manufacturing applications.

Thermal processing to relieve stresses and enhance mechanical properties.

Precision machining for tight tolerances and fine finishing of parts.

Blasting, polishing, passivation for a premium finish on functional parts.

Non-destructive testing, CT scanning, and dimensional inspection for quality assurance.

5–7 working days depending on geometry and material.

5–7 working days depending on geometry and material.