Additive Industries

About Us

Additive Industries Pvt Ltd was established in 2021 with ambitious of providing technical services to Aerospace industries,

Defense sector, Space sector, Automobile and Medical industries.

Our company is committed to provide technological services

such as 3D CAD modelling and simulation, re-engineering services, dimensional analysis, Non-destructive testing, and mechanical

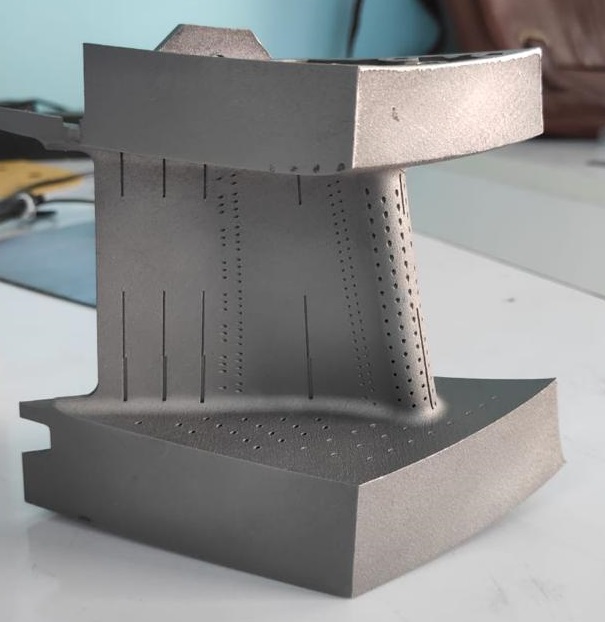

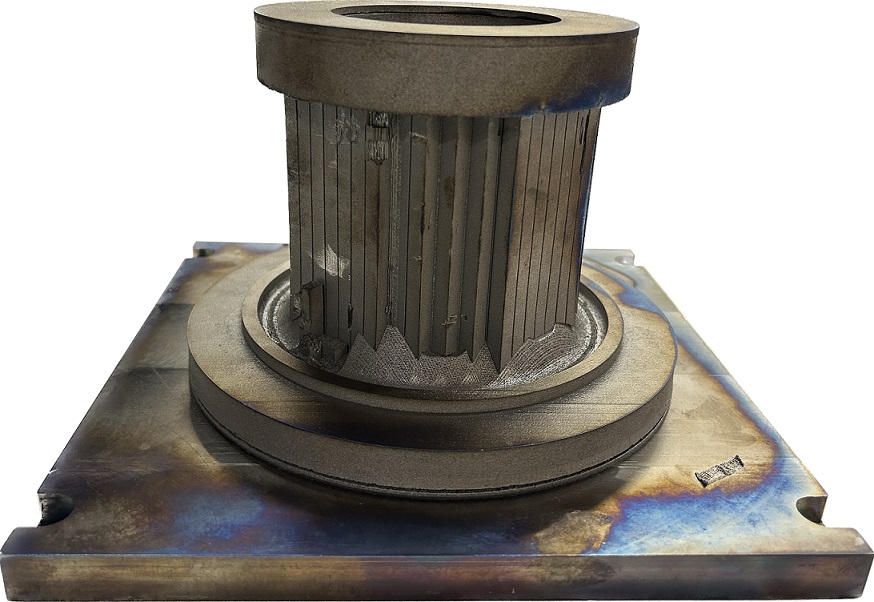

and material characterization. We have provided manufacturing solution for various aerospace component with value addition such

as complex part realization, part consolidation, weight optimization in very short time.

We have strong network in supplying various consumables

and secondary services such as metal powders (Titanium, Nickel, Aluminium, and Iron alloys), powder sieving and storage equipment.

At Additive Industries Pvt Ltd, we are committed to driving innovation and exceeding our clients' expectations. By partnering with us, you can trust that you are working with a reliable and forward-thinking company that strives for excellence in every aspect of our services.

Our Services

FDM, Metal 3D-Printer

We provide high-quality 3D printers for additive manufacturing, including FDM technology. Our printers are customizable to meet our clients' needs and are designed to deliver accurate and precise prints. With our expertise in the AM industry, we help our customers achieve their printing goals and stay ahead of the competition

Selling of AM Powder

We provide a wide range of AM powder for Additive Manufacturing, including metals, plastics, ceramics, and composites. We offer high-quality materials that are specifically designed for use in 3D printing applications, ensuring that you get the best possible results from your 3D printing projects.

Training Student Community on AM industry

Our experienced trainers will guide students through each step of the AM workflow and provide valuable insights into the industry's current trends and future potential. By completing our AM training program, students will be equipped with the knowledge and skills to succeed in this rapidly growing field.

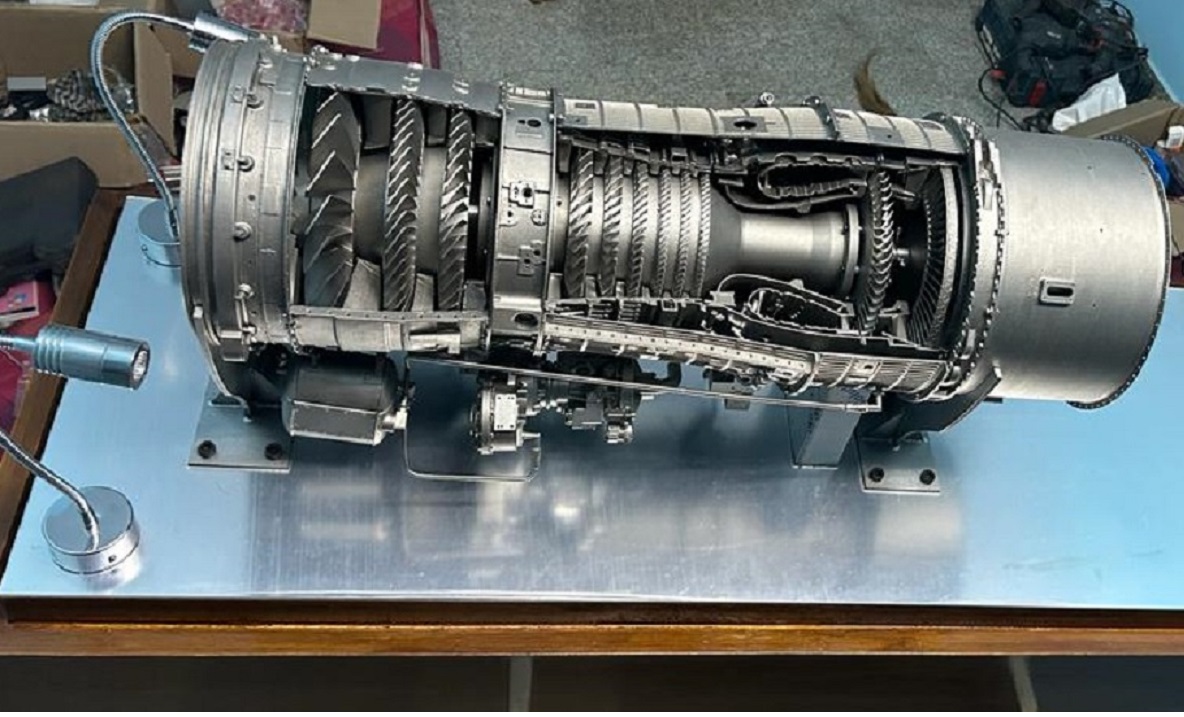

Direct Metal Printing

We offer a range of direct metal printing services using state-of-the-art equipment and materials, including titanium, stainless steel, aluminum, and other alloys. Our direct metal printing services are ideal for producing complex, high-strength parts that require exceptional accuracy and durability.

Our Portfolio

Latest AM Blogs

How India’s Additive Industry is poised for growth

The highlight of the magazine is the cover story – Unlock Additive, Unleash Additive. It talks about the various new developments in the Indian AM space that makes the Indian market an attractive prospect for Indian as well as foreign brands. It conveys that the Indian Additive Industry is not unlocked and will unleash itself in this decade.

ADVANCING ADDITIVE MANUFACTURING IN INDIA, THE WORLD’S FIFTH-LARGEST ECONOMY

The Indian Ministry of Electronics and Information Technology (MeitY) announced a National Strategy for Additive Manufacturing on February 24, 2022. In this interview, 3D Printing Industry spoke with a Government official and IIT Bombay to gain insights about the strategy and how the Indian AM industry is developing. “The aim is to increase India’s AM market share to 5% of the global market by 2025, with a goal of adding nearly $1 billion to the GDP

Envisioning Indian 3D Printing Industry’s path to Global Leadership

3D printing will soon celebrate its fortieth anniversary since Charles Hull first patented the technology in 1984. It has come a long way since then. And, despite multiple hype cycles, the industry is much stronger today than it has ever been. This robustness can be seen in the Indian 3D printing industry as well, so I believe the time has come to chart a course for the industry’s next phase of development.

Frequently asked Questions

AM technologies enable the manufacturing of complex shapes with customized and multifunctional material properties in an additive fashion. In the past few years, AM technology has been revolutionizing the manufacturing industry due to the wide range of product development. Thus globally, the AM process forms the foundation of future manufacturing and can potentially complement Industry 4.0

· Manual post-processing

· Limited data preparation and design capabilities

· Part to part variation

· Lack of industry standards and infrastructure

· Lack of insight and expertise

· Initial investment

· Disjoined AM ecosystem